Product

iDASProduct > Development Data Acquisition / Analysis System

The need for high-speed data acquisition

The need for high-speed data acquisition

-

Smart logging system

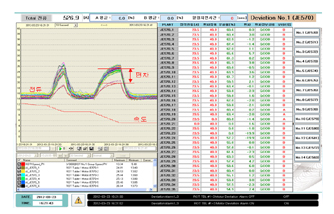

In a continuous process control plant, it is important that all control facilities operate exactly as planned. While the conventional monitoring / control systems collect data in seconds, iDAS can communicate in ms and save the data as a file. The data measured in ms can be used not only for quality analysis, failure analysis, but also for diagnosis of failure prevention. For example, in a continuous process control system, data can be collected and analyzed in ms to provide accurate quality analysis and precise control activities.Accurate process analysis and quick decision making

iDAS provides accurate process analysis function by managing alarms and trends in ms, and helps you to make quick decisions with flexible and convenient usage.

10ms motor current analysis screen -

Useful to Maintenance

Fault Analysis

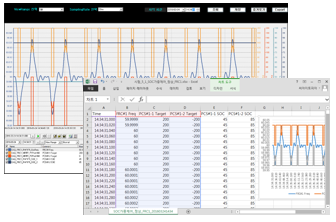

It is able to fault analysis in detail and accurate through the data history measured in ms when a fault occurs due to equipment malfunction or trip

Useful to Decision Prioritize Maintenance

By contributing to determining maintenance priorities based on visualized data, you can shorten maintenance time, reduce maintenance costs and maximize maintenance effectiveness

Preventive Maintenance

iDAS system helps preventive maintenance because it measures not only the fault condition but also the symptom of failure

▲ 10ms power grid frequency analysis screen

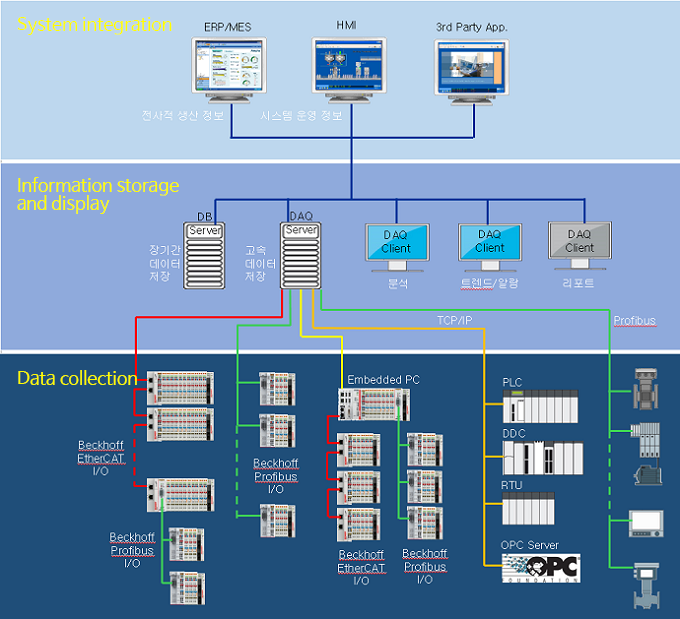

System Configuration

System Configuration

Integrated Interface Support to access necessary information anytime, anywhere

iDAS provides all interfaces from field data collection to higher-level systems so that all stakeholders in the enterprise can utilize the data

Specification

Specification

| Contents | Specification |

| Architecture | Based on Server-Client structure |

| Data Acquisition & Saving | Storing trend and alarm data Minimum resolution : 1ms Samplaing mode : Fixed cycle mode, Event trigger mode The number of data channel : 128 ~ 4096 |

| Data Source | Beckhoff - EtherCAT I/O Toshiba - V3/S3 PLC Hitachi - R700/R900 PLC Mitsubishi - Melplac PLC POSCOICT - Postar DDC Modbus (Ethernet / Serial) Profibus OPC |

| Trend | Number of pens : 36 Number of Cursors : 2 View saving Display mode : Min / Max / Avg / RMS Avg / Sample Statistical data display Y axis multi-scale display Screen saving Output data Drag & Drop operation functionality |

| Alarm | Type : Digital Alarm, Analog Alarm Alarm page : On Alarm List, Summary Alarm List Linking alarm information and trend information |

| Report | Type : Event report, production report, periodic report, alarm report Output method: Html, PDF, CSV, PNG or print Reporting Services in Microsoft SQL Server |

| Visualization tool | Process screen creation and symbol animation Scripting Query and Table display Support for various charts |

| Special Modules | Analysis and diagnostic modules Length Trend Module |

CiTopia Co., Ltd | A-604 SK Twin Tech Tower 119, Gasan Digiral 1-ro Geumcheon-gu Seoul, Korea | 08589 | Tel : 82-2-868-9060 | Fax : 82-2-868-9064

Pohang Office | 2F Deungchon Building, 356 Naengcheon-ro, Ocheon-eup, Nam-gu, Pohang-si, Gyeongsangbuk-do, Republic of Korea | 37886 |

Tel : 82-70-7854-9117 | E-mail : citopia@citopia.co.kr

Copyright ⓒ 2015 CiTopia Co., Ltd. All rights reserved.

Pohang Office | 2F Deungchon Building, 356 Naengcheon-ro, Ocheon-eup, Nam-gu, Pohang-si, Gyeongsangbuk-do, Republic of Korea | 37886 |

Tel : 82-70-7854-9117 | E-mail : citopia@citopia.co.kr

Copyright ⓒ 2015 CiTopia Co., Ltd. All rights reserved.