Product

Valve leakage diagnosis systemProduct > Valve leakage diagnosis system

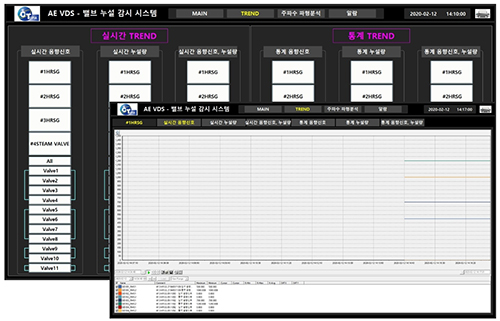

Acoustic emission sensor and data collection technology are used for various important valves used in industrial sites to monitor and pre-diagnose internal micro leakage and equipment abnormality in real time, and apply additional “ambient noise reduction algorithm” We have completed the localization development of a high-performance, low-cost “valve internal leakage diagnosis system” with improved reliability and precision. In particular, we focused on predictive maintenance and proactive diagnosis for building a smart factory, which is the topic of the 4th industrial revolution these days, so that the machine learning-based AI platform can be supported to minimize the intervention of maintenance personnel.

Solution Outline

Advantages of Development

Advantages of Development

Improvement of measuring method using acoustic emission technology.

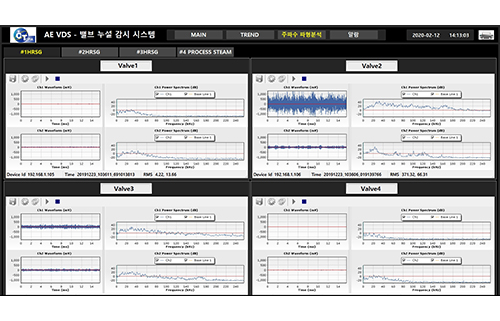

- Simultaneous measurement of various valves and multiple valves.

- Real time Leak measurement and Valve status visualization.

- Integrated diagnostic and measuring device Built in Preamplifier.

- Easy on-site installation and communication configuration

(provide tool for site support and various communication configurations ).

Ambient noise filtering algorithm such as noise and vibration.

- Possible to measure fine leakage due to noise attenuation.

- Possible Precise diagnosis through Sound Level Analysis and Pattern Analysis.

- Improved reliability and accuracy of measurement results.

- Support Big data based platform service

- Auxiliary sensor input can be used to improve measurement accuracy by correlating measured data.

- 100% localization technology enables low-cost supply and pioneering overseas markets

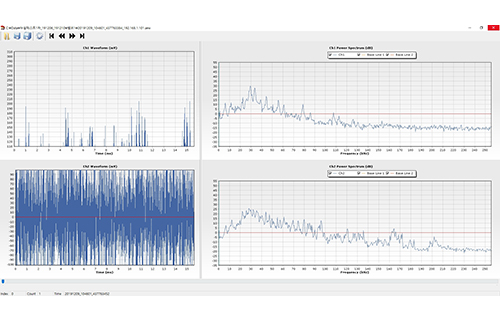

Average Voltage (RMS) Analysis

Wave form Analysis

Frequency Analysis

Pattern Analysis

Necessity of Development Technology

Necessity of Development Technology

Valve Leakage : Occurs frequently in most industrial sites

- Long Term Leakage : Huge increase in economic losses

- Closed Condition maintenance valve : Very susceptible to leakage under high temperature and high pressure conditions

- Hazardous Gas Leakage: Serious harm to human and material resources

- Preventing major accidents: increasing customer demand for early detection of internal leakage

Effect

Effect

- Prevent damage expansion by detecting damage of valve packing and seat

- Prevent unexpected Accidents caused by Valve Internal Leakage Diagnosis

- Improved Equipment efficiency and reduce Heat Loss due to decrease Leakage Rate

- Possible to Predictive maintenance by analyzing the condition of valve and Reduce Maintenance Cost

- Fully automated analysis ensures facility reliability and improves working conditions

Development goal of technology

Development goal of technology

1) Investigation of valve leakage status in steelworks and other industrial sites (chemical, semiconductor, power plants, etc.)

- Analysis of existing leak monitoring methods and systems

- Analysis of acoustic characteristics according to various valve leakage shapes

- Leakage basic experiment and optimal signal analysis method analysis for each valve

- Basic experiment and signal analysis for each valve according to fluid, pressure and temperature

2) Field valve simulation device configuration and field test

- Leak Data Acquisition and Testing

- Various signal processing and spectrum analysis of sound signal acquisition data

- Diagnostic algorithm and program design

- Final selection of measuring method / range according to valve environment and monitoring method

- Experimental device configuration and testing for field process characteristics

3) Commercialization of valve leakage monitoring system (prototype)

- Leak test reliability review and commercial leak test technology development

- Field portable and database-based fixed system development

Final development goals

AI platform development for pre-leak diagnosis of various valves based on machine learning using big data

Patent Technology Application Items

Patent Technology Application Items

- Business Cooperation MOU with Korea Hydro & Nuclear Power Co., Ltd. : “Diagnosis and Monitoring of Valve Internal Leakage Using Acoustic Emission Measurement" Normal license contract(5 Years)

- Industrial Property application( Patent Technology ):

Valve internal leakage diagnosis device and method (Domestic Patent 10-0888320)

Valve leakage diagnosis apparatus and method for removing ambient noise (Domestic Patent 10-0836043)

Differentiation from domestic and foreign competitors

Differentiation from domestic and foreign competitors

| Item | Competitive products | Development products |

|---|---|---|

| Analytical Precision | Relatively low | Relatively high |

| Accurate diagnosis is difficult due to analysis by sound level | Precise diagnosis through sound level and pattern analysis. | |

| Highly affected by ambient noise such as noise and vibration | Applies noise reduction algorithms such as noise and vibration. | |

| Microleakage | difficulty | possible |

| Difficulty in identifying fine leaks by analyzing only acoustic levels | Noise reduction algorithm (patented) enables fine leakage measurement. | |

| Pattern Analysis | difficulty | possible |

| Big data-based pattern analysis | ||

| How to install | sinuosity | ease |

| (Coaxial cable connection from field sensor to DAQ board) | (Use wired / wireless hybrid network from field sensor to diagnostic system) | |

| Communication method | Method by wire (coaxial cable) | Supports various wired and wireless networks such as WiFi, LAN, CDMA, and LTE |

| Integrated surveillance | Difficulty in remote / real time monitoring of many valves | Remote and real-time monitoring of various valves and multiple valves and measurement of status values. |

| price | high price | More than 50% cheaper due to localization |

| System configuration | difficulty | Simple |

| (Sensor + Preamplifier + Me Certified Amplifier + DAQ Board) | Sensor + Embedded System Built-in Diagnostic Device) | |

| Surveillance system | Provide simple monitoring screen | Provide various screens such as status diagnosis, alarm, trend, report |

| Maintenance | Difficulty (Difficulty in maintenance with foreign products) | Easy (pure domestic development technology except sensor) |

| Sensor installation | Difficulty (installed by welding to the valve body | Easy (Easy installation and replacement due to integrated waveguide and ring clamp) |

Pohang Office | 2F Deungchon Building, 356 Naengcheon-ro, Ocheon-eup, Nam-gu, Pohang-si, Gyeongsangbuk-do, Republic of Korea | 37886 |

Tel : 82-70-7854-9117 | E-mail : citopia@citopia.co.kr

Copyright ⓒ 2015 CiTopia Co., Ltd. All rights reserved.

Catalogue

Catalogue